Material testing is one of the most important and necessary parts of complete vehicle testing. Technically speaking testing of materials is done to check whether a bullet penetrates protection or not; however you can find lots of different nuances here - the initial velocity of the bullet, the yaw angle, hardness of the material at each spot - all these points have their importance, so for the statistically reliable results multiple tests have to be carried out.

Several standards on testing different materials have been developed. For example, the Association of Research Institute of protective materials and structures (VPAM), which includes 14 European testing bodies, developed the protection classes sorted by the kinetic energy of the bullet. Another widespread standard is STANAG 4569 which was adopted by NATO. According to the VPAM standard APR 2006 three samples are taken for the testing of the material, each is shot at by 3 bullets. The standard STANAG 4569 requires 8 shots at each sample; yet we often prove that even this number might not be sufficient.

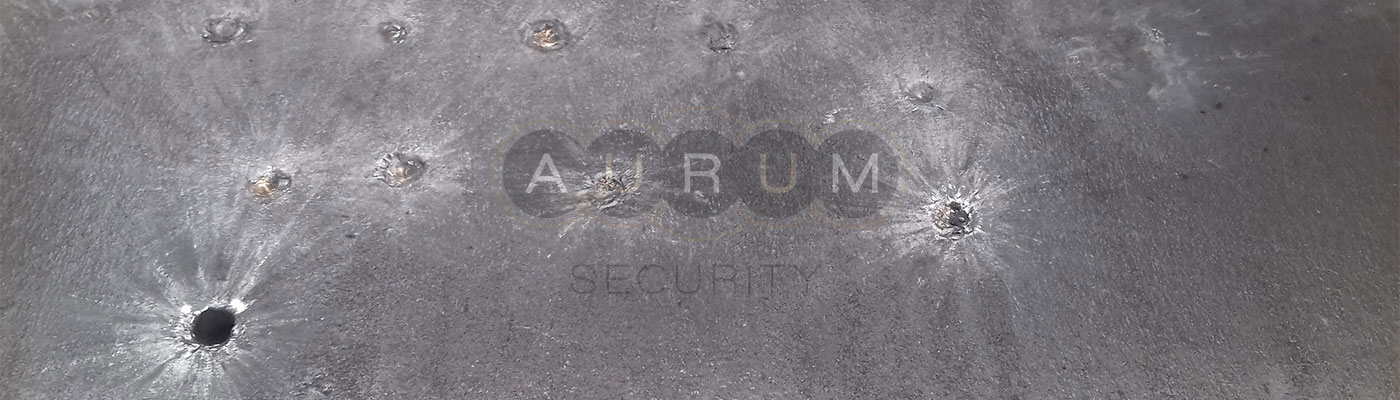

Recently we tested some certified material which withstood nine shots, but was penetrated by the tenth one; you can see test results in the photo below. The lesson learnt is that the certificate might not give reliable guarantee of protection; only numerous tests can ensure that - hence we do not rely on certificates and conduct tests ourselves. This brings additional costs but our experience shows that it is unavoidable to be sure on the quality of our products.